A Morning Moment, A Lasting Mark

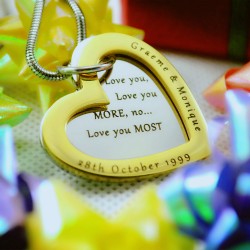

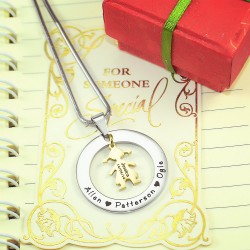

There’s something truly special about those quiet moments before a big occasion, isn’t there? You know the ones I mean – that little pause, a breath held, just before the whirlwind begins. I was chatting with a friend the other day, reminiscing about his wedding morning, and he spoke about the nerves, the excitement, and that unexpected calming feeling he got when his bride presented him with a beautifully wrapped box. Inside, tucked away in soft velvet, were the most magnificent cufflinks. It wasn't just the shine of the metal, or the perfect weight in his palm; it was the story held within them, a subtle nod to their shared journey. It made me think about how some pieces of jewellery, like a cherished family heirloom or perhaps even a Double initial necklace you might gift a loved one, carry far more than just monetary value. They carry a whisper of love, a promise, a memory.

He laughed as he recalled trying to fasten them with slightly shaky hands, the buttonholes on his crisp white shirt suddenly seeming impossibly small. But once they were in place, gleaming just so at his cuffs, he said he felt a quiet confidence settle over him, a sense of readiness for the day ahead. That feeling, that connection to a tangible piece of personal artistry, that's what we truly strive for when we're crafting something. It’s not just about making something pretty; it's about crafting an extension of someone’s story, a silent, elegant declaration.

It reminds me of the intricate beauty you find in a Handmade Trinity Ring, a piece that symbolises eternal connection, or how a simple everyday piece can become profoundly meaningful. We pour so much thought into every curve, every polished surface, because we know these aren't just objects. They become part of someone’s most precious moments, anchors for significant memories. They're worn, admired, and then, one day, passed down.

And speaking of passing things down, let’s talk about those perfect finishing touches, the little details that can transform an outfit from good to absolutely grand. We've been putting a lot of love into something that, while perhaps not as overtly sentimental as a Custom Initial Necklace for a partner, certainly carries a punch when it comes to style and personal flair.

You see, we've had countless requests over the years for pieces that cater to the discerning gentleman. Folks are always on the lookout for something that speaks volumes without shouting, something refined yet completely unique. Whether it's for an anniversary, a milestone birthday, or as part of the grand ensemble for a wedding day, people want a gift that feels deeply considered. We're talking about those essential, thoughtful, Jewelry Gifts to Share.

It’s not often you find something that balances that classic appeal with a touch of modern, personalised charm quite so effortlessly. We knew we wanted to create something truly special, something that would stand the test of time, both in terms of its durability and its design. The challenge, as always, was how to take a traditional accessory and infuse it with that distinctive touch that makes it unequivocally ‘The Handmade’.

We started sketching, playing with different shapes, fonts, and finishes. We thought about the occasions these would be worn, the outfits they would complement, the stories they would tell. We looked at everything from antique signet rings to contemporary sculptures, drawing inspiration from all corners to ensure our vision was fresh, yet rooted in timeless appeal. The goal was to create a piece that felt both utterly personal and universally sophisticated. And, as you might gather, we landed on something rather splendid, something we're incredibly proud of, a piece that brings a contemporary twist to a classic. That would be our very special Script Initial Cufflinks for Men Gold.

The Journey from Raw to Radiant: Our Material Story

Now, let's pull back the curtain a little bit and talk about what actually goes into making these beauties, starting right at the very beginning – the materials. You see, when you’re creating something that’s meant to last a lifetime, something like a Custom Coordinates Bracelet Gift that marks a truly special place, the foundation simply has to be impeccable. We're not just grabbing materials off the shelf; there's a meticulous, sometimes even a bit obsessive, process behind every single ingot of silver that comes through our workshop doors. It’s a journey that begins long before any design sketches hit the paper, rooted deeply in the principles of ethical sourcing and unwavering quality.

Our primary material for these cufflinks is top-grade 925 Sterling Silver. Why 925? Well, it’s the industry standard for fine silver jewellery, meaning it's 92.5% pure silver, with the remaining 7.5% being other metals, typically copper. This small but mighty addition of copper is absolutely vital, by the way. Pure silver is incredibly soft, far too malleable to hold its shape or withstand the daily knocks and bumps that jewellery encounters. The copper gives it that much-needed strength, durability, and allows us to work it into those intricate designs without it bending out of shape at the slightest touch. It’s a delicate balance, achieving that perfect alloy, ensuring the metal is both workable and robust.

But it’s not just about the composition. It's profoundly about where that silver comes from. We work exclusively with trusted, certified suppliers here in the UK who not only meet but exceed strict ethical and environmental standards. We spend a lot of time building genuinely strong relationships with these folks, visiting their refineries, understanding their meticulous processes, even delving into their responsible waste management systems. We want absolute certainty that our materials are sourced responsibly, that the people involved in extracting and refining them are treated fairly, with safe working conditions and equitable wages, and that the environmental impact is minimised at every turn. It’s a commitment we take incredibly seriously, because every single step in our supply chain reflects on the final piece, and ultimately, on the integrity of our brand. It’s about building something beautiful with integrity, from the ground up, literally.

Then comes the gold plating – a whole other fascinating chapter in our material story. Our Handmade Gold Script Initial Cufflinks aren't just given a quick dip and a hopeful glance; they undergo an 18k gold plating process that's specifically designed for longevity, a truly luxurious finish, and a rich, enduring glow. The process is a careful ballet of chemistry and precision, requiring specialised equipment and an expert touch. We’re aiming for that lovely, warm lustre of real gold, and for that to happen, the plating needs to be applied with incredible uniformity and adherence.

The gold itself, the 18-carat gold that makes up the plating, is sourced with the same level of scrutiny and care as our silver. It's 75% pure gold, precisely mixed with other metals to give it the necessary strength and the desired hue that characterises 18k gold. This particular caratage is ideal for plating because it offers a beautiful, deep colour without being too soft, ensuring it will bond perfectly and stand up to wear. The thickness of the plating is also absolutely crucial – our cufflinks have a substantial 1.5mm thickness. This isn't just a fleeting surface shimmer that will rub off with a bit of wear; it’s a robust, enduring layer that will stand up to daily use and retain its deep lustre for many, many years, ensuring that the piece feels truly premium and lasts as long as the memories it helps create. It’s the difference between something that looks good for a season and something that becomes a treasured heirloom.

Managing this complex supply chain, from the initial raw silver grains and gold alloys to the final, meticulous gold bath, is a bit like conducting an incredibly precise orchestra. Each supplier, each batch of material, each chemical solution in the plating process, has to be perfectly harmonised and synchronised. There are multiple, rigorous quality checks along the way, right from the moment the raw material arrives at our workshop. We’ll check for purity, for any minute inclusions, for consistency in grain size, and for dimensional accuracy of the raw forms – whether it’s sheet, wire, or casting grain. If it doesn’t meet our exacting standards, it simply doesn’t get used, no exceptions. There are absolutely no shortcuts when you're crafting something meant to be cherished for generations. It’s a continuous, open conversation with our trusted suppliers, a constant refinement of our procurement processes, all to ensure that when you look at something like our Shop Personalized Tree of Life Necklace or any other item from our collection, you're getting something made with unwavering commitment to excellence and a clear conscience.

This logistical dance, moving precious metals from refinery to specialist plater, then finally to our workshop, involves a surprisingly intricate network. We don’t just order; we track, we verify, and we ensure every consignment is secured and insured, because these are not just raw materials, they are the very genesis of someone's future cherished possession. The complexity lies not just in finding the best materials, but in maintaining a transparent and accountable chain of custody. Every single gram is accounted for, traced back to its origin, providing us with a clear narrative of its journey. This thoroughness is not just for our peace of mind; it's a promise of authenticity and responsible stewardship.

The profound significance of this meticulous supply chain management goes far beyond mere commercial efficiency. It speaks to the very heart of what we do: creating jewellery with integrity, honesty, and a tangible sense of purpose. It means that when you eventually hold one of our pieces, perhaps one you came to Find out more about through our discussions, you can be sure that its creation hasn't caused harm or exploited anyone along the way. It’s about craftsmanship with a conscience, where every step, from the earth to your hand, reflects our deeply held values. This diligent oversight ensures that every piece leaving our studio carries with it a story of care, responsibility, and an uncompromising dedication to lasting beauty.

More Than Just an Accessory: The Cufflinks' Enduring Spirit

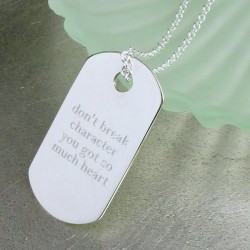

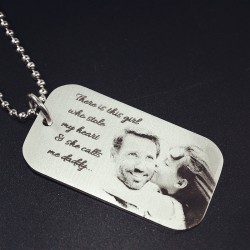

So, with all that passion and precision poured into the raw materials, what does it mean for the finished product? Our Script Initial Cufflinks for Men Gold are, quite simply, more than just a smart accessory. They are a statement, a subtle whisper of individuality, and a testament to enduring style. Imagine them gleaming at the cuffs of a crisp shirt, catching the light as someone gestures or laughs. They add a refined touch, a polish that says, "I pay attention to the details."

They are built with purpose, designed to be that "contemporary twist on a classic design" that we talked about earlier. The round disc diameter of 1.5cm (or 0.59 inches) is just perfect – substantial enough to be noticed, but not so large as to be flashy. The thickness of 1.5mm (0.059 inches) provides a satisfying weight and a feeling of robustness, a far cry from flimsy, mass-produced alternatives. These aren't throwaway items; they are meant to be cherished, kept, and possibly even passed down through generations. They truly are a perfect gift for someone special, much like the timeless beauty of a Handmade Flower Ring.

What makes them truly unique is, of course, the personalisation. The script initial adds that deeply personal element, turning a beautiful object into a story. It could be the wearer's own initial, a tribute to a loved one, or even a symbolic character that holds special meaning. This makes them a hugely popular choice, especially as wedding gifts, where they truly are sure to be treasured for years to come. Brides gifting them to grooms, groomsmen receiving them as a token of thanks, or even parents presenting them to their son on his big day – they encapsulate sentiment and celebration beautifully.

Caring for these cufflinks is straightforward, much like looking after any beloved piece of fine jewellery, perhaps even a Lucky Horseshoe Necklace. Regular gentle cleaning with a soft cloth will keep them sparkling. For those times they need a bit more attention, a mild soap and warm water solution, followed by a thorough drying, will do the trick. We always advise storing them in their original box or a soft pouch to prevent scratches, keeping them away from harsh chemicals like perfumes or household cleaners which can dull the gold plating over time. It’s a small effort for a lifetime of gleam.

And here's a little thought that extends beyond just these cufflinks. We often chat with our customers about the longevity of their jewellery, and how pieces can evolve with them. For example, while these cufflinks are perfect as they are, we always encourage thinking creatively about other pieces in your collection. Did you know gemstones can be reset by professional jewellers, breathing new life into a piece? Or that necklaces can be reworked into bracelets or combined with other necklaces to create a modern, multi-chain design? This concept of adaptability and re-imagining is something we genuinely champion. So, go on, be creative and look for ideas online for recycling those outdated pieces. There’s so much potential for transformation, turning something old into something wonderfully new again. It’s a sustainable approach to luxury.

It’s this enduring quality, this blend of aesthetic appeal, personal meaning, and practical durability, that makes these cufflinks so special. They are not merely an item to fasten a cuff; they are a conversation starter, a quiet statement of confidence, and a lasting symbol of significant moments. They're designed to be worn, enjoyed, and ultimately, to become a part of the wearer's personal narrative, evolving with them through life's many occasions.

From Concept to Cuff: The Artisan's Touch

The Spark of an Idea: Design and Digital Crafting

Alright, buckle up, because this is where the real magic happens, the part I truly adore – getting our hands dirty, well, meticulously clean, actually! Every single piece, even something as seemingly simple as a cufflink, starts with a flicker of an idea, a sketch, and then, rather surprisingly, a lot of digital wizardry. It’s not just about drawing a pretty picture; it’s about translating that vision into a precise, workable blueprint for metal. We use sophisticated CAD (Computer-Aided Design) software, a truly remarkable set of tools, to create a detailed 3D model of each cufflink. This isn't just for fun; it allows us to perfect every curve, every dimension – the generous 1.5cm (or 0.59 inches) round disc, the robust 1.5mm (0.059 inches) thickness – with incredible accuracy down to fractions of a millimetre. It’s where we ensure the script initial will sit beautifully within the round, where we meticulously account for potential metal shrinkage that occurs during the casting process, and where we visualise the final piece in stunning, lifelike detail, almost as if you can reach out and touch it. This is also the stage where we generate a high-resolution visual proof for our customers, a little sneak peek, ensuring they're absolutely thrilled with how their chosen initial will appear before we commit to any metal. It’s a wonderful, collaborative process, making sure their vision perfectly aligns with ours before we even touch a piece of raw material.

Once the digital design is locked in and given the official green light – usually after a happy customer nod – we then prepare for the physical manifestation. This involves creating a highly detailed wax model, often using a state-of-the-art 3D printer specifically designed for jewellery applications. This isn’t just any old printer you’d find in an office; it’s one that can create unbelievably fine details, capturing the delicate flourishes of the script initial and the precise curvature of the cufflink disc with astonishing fidelity. This wax model is essentially the intricate template for our casting process, and its accuracy is absolutely paramount. Even the tiniest imperfection at this wax stage will be magnified in the final metal piece, a small ripple becoming a noticeable flaw. So, we scrutinise these wax models under powerful magnification, checking every single line to ensure it’s crisp, every surface is impeccably smooth, and every dimension is spot-on. It's a testament to the fact that even in our modern, digital age, the human eye, an experienced hand, and a meticulous touch are still utterly irreplaceable for achieving true perfection. It's all part of the dedicated craftsmanship that goes into something as delightful and detailed as a Handmade Flower Ring, a piece crafted with passion at every single stage.

The Fiery Art of Metal Forming: From Wax to Silver

Now, for the truly exciting part – transforming that delicate wax into solid, gleaming silver. We employ a traditional, revered method known as 'lost-wax casting', a technique that has graced workshops for thousands of years, and for very good reason: it’s incredibly effective for faithfully reproducing intricate forms and detailed designs. First, the individual wax models of the cufflink discs are carefully attached to a central wax 'tree', a bit like branches on a miniature Christmas tree, with multiple cufflink components ready to be cast simultaneously. This method maximises efficiency while maintaining individual piece quality. This entire wax tree is then meticulously encased in a special plaster-like investment material, creating a robust, heat-resistant mould around our wax creations.

Once the investment material has set hard, a process that takes several hours to achieve the right consistency and strength, the mould is placed into a high-temperature kiln. Here’s where the 'lost-wax' part truly comes into play: the wax melts away completely, leaving behind a perfect, hollow cavity within the investment mould, an exact inverse of our desired cufflinks. This kiln process also thoroughly bakes the mould, making it incredibly strong and durable, ready to withstand the intense heat and pressure of molten metal. It’s a controlled burn, precise and methodical, ensuring the mould is purged of all impurities and perfectly prepared to receive its precious cargo. The air in the workshop gets wonderfully warm during this stage, filled with that unique, earthy scent of heated plaster and a palpable sense of anticipation for the transformation about to occur.

Next, the molten 925 Sterling Silver is either poured by hand with incredible care or injected under vacuum into the hot mould. The silver, heated to just the right, precise temperature (we're talking specific degrees here to ensure optimal flow and minimal porosity), flows rapidly into every tiny detail of the hollow cavity, faithfully reproducing the original wax design down to the microscopic level. It's a moment of immense truth, watching the liquid silver fill those spaces. Once the silver has cooled and solidified completely within the mould, which takes time and controlled environment, the investment material is carefully, painstakingly broken away, revealing the nascent silver cufflink components. They’re still attached to the 'tree' at this point, looking a bit rough around the edges, covered in a slight, frosty layer, but absolutely bursting with potential. It’s always an incredible thrill, seeing the raw metal emerge, hinting at the beauty to come. It's a foundational step, much like the careful start for a Lucky Horseshoe Necklace, where the integrity of this initial casting ensures the eventual perfect form and lasting strength of the finished piece.

Bringing Forth the Brilliance: Finishing and Polishing

After casting, the individual cufflink discs are carefully cut from the silver tree using specialised saws. This is followed by an extensive initial cleaning process to remove any remaining investment material and fire scale from the casting. Then, the real, intensive handcrafting begins with the 'filing and sanding' stage, a true test of patience and skill. Each cufflink component is meticulously filed by hand to remove any casting 'flash' – excess metal that forms where the mould halves met – or rough edges. This requires an incredibly steady hand, a keen eye, and a deep understanding of the metal's contours, smoothing out every curve and ensuring perfectly crisp edges where needed. Different grades of precision files are used, moving from coarser to progressively finer, gradually refining the shape and achieving the desired exact dimensions of the 1.5cm diameter disc.

Following filing, the rigorous sanding process begins. We use various grades of high-quality abrasive sandpaper, starting with a coarser grit to eliminate any remaining scratches or marks from the filing, and progressively moving to finer and finer grits, sometimes going through six or seven different stages. This is a crucial, time-consuming step for achieving that perfectly smooth, uniform surface, ready for polishing. It’s a rhythmic, almost meditative process, where you can literally feel the metal transforming under your fingers, getting smoother and smoother with each pass, until it's like glass. This stage is all about preparation – getting the surface absolutely pristine, free of any imperfections, before the final polishing. We always work in a superbly lit area, often under bright, directed lamps, to spot even the tiniest scratch or imperfection that might spoil the final, radiant finish. It’s a painstaking commitment to flawlessness.

Then comes the initial polishing, using a series of motorised polishing wheels and various specialised compounds, each designed for a different purpose. This is where the silver really starts to come alive, transitioning from a matte, sanded finish to a brilliant gleam. We use different types of soft mops – cotton, felt, or muslin – and a range of polishing rouges, each containing different abrasive qualities, designed to achieve a specific level of lustre. It’s a skill learned over years, knowing just the right amount of pressure to apply, the perfect angle to hold the piece against the spinning wheel, and the precise duration for each stage to bring out that radiant, mirror-like shine without over-polishing or losing any of the delicate details of the script initial. This is a wonderfully messy business, with polishing compound dust everywhere, but it’s deeply satisfying, as the true, inherent beauty of the metal begins to powerfully emerge under our hands.

The Personal Touch: Script Initialisation

With the silver discs polished to a beautiful sheen, it’s time for the star of the show: the script initial. Although the initial is designed digitally with artistic flair, its actualisation onto the silver disc requires incredibly careful and precise engraving. We employ a high-precision laser engraving machine for this crucial step. Why laser? Because it offers unparalleled accuracy, the ability to reproduce even the most intricate script fonts with astonishing crispness, and perfectly clean lines, which is vital for a personalized piece. The exact digital design is fed into the machine, and a focused laser beam carefully etches the initial onto the surface of the silver disc. It’s truly mesmerising to watch, as the machine robotically and precisely follows the contours of the chosen letter, creating that unique, deeply personal mark.

However, it’s not just a matter of pressing a button and walking away. Even with a laser, there’s a significant art and science to achieving perfection. We carefully calibrate the laser’s power, its speed, and the number of passes, ensuring the depth of the engraving is just right – deep enough to be permanent and clearly visible, creating a lovely tactile impression, but not so deep as to compromise the structural integrity of the 1.5mm thick disc. The slightest miscalculation in these settings could mar a precious piece, rendering it unsuitable, so meticulous pre-setting, rigorous testing on scrap metal, and continuous monitoring are absolutely vital. It’s a powerful testament to how modern, cutting-edge technology and traditional, discerning craftsmanship can truly work hand-in-hand to create something truly exceptional, utterly unique, and profoundly personal.

The Golden Touch: 18k Gold Plating

Once the silver discs with their personalised initials are perfectly polished and engraved, they are subjected to an intense, multi-stage cleaning protocol. This ensures there’s absolutely no dust, microscopic debris, or even the slightest trace of oil or fingerprints on the surface. This is a supremely critical step before plating, as any contamination, no matter how minute, will prevent the gold from adhering properly, leading to an imperfect finish. The pieces go through a series of ultrasonic baths with specialised cleaning solutions, followed by distilled water rinses, making them surgically clean and chemically activated, ready for their glorious golden transformation.

Then, the cleaned cufflinks are carefully suspended on custom-made racks, ensuring maximum surface area exposure, and gently immersed in an electroplating bath containing a carefully formulated 18k gold solution. This is where the magic of electrochemistry happens, a delicate balance of science and art. A precise and controlled electrical current is passed through the solution, causing the positively charged gold ions to be attracted to and deposit evenly onto the negatively charged surface of the silver cufflinks. The thickness of this gold layer is meticulously controlled to achieve that robust 1.5mm plating mentioned earlier – a thickness that gives it incredible longevity, resistance to wear, and that truly luxurious, substantial feel, far beyond a mere decorative flash. This isn’t a quick, superficial dip; it’s a controlled, deliberate, and layered process that ensures a consistent, durable, and genuinely beautiful layer of real gold.

The electroplating process itself is a delicate science, requiring constant, vigilant monitoring of a myriad of factors: the precise temperature of the bath, the pH levels of the solution, the gold concentration, and the current density. Our plating specialists are true experts, constantly adjusting these parameters to ensure the colour is perfect – that rich, warm hue of 18k gold – and that the adhesion to the silver base is absolutely flawless. After the plating is complete, the cufflinks are rinsed thoroughly again to remove any chemical residue and then subjected to another round of incredibly gentle, final polishing. This delicate buffing brings out the ultimate, glorious shine of the gold, removing any microscopic haze. This is the moment when the piece truly comes alive, transformed from a silver disc into a brilliant, golden emblem of personal style, ready for its final transformation.

The Grand Finale: Assembly and Perfection

With the beautiful, gold-plated, initialled discs now shimmering with their golden lustre, the very final stage is attaching the robust cufflink mechanism. This is another area where absolute precision and uncompromising durability are paramount. We use a high-quality, swivel-back cufflink fitting, chosen for its smooth action and long-lasting strength, which is then carefully and securely soldered to the very centre of the back of the disc. This soldering process requires immense skill, a delicate dance with heat – too much heat and you risk melting the carefully applied gold plating or even the underlying silver; too little and the bond won’t be strong enough. It’s about finding that sweet spot, that perfect molten moment.

Each cufflink mechanism is individually placed and painstakingly soldered by hand, using a jeweller’s torch and fine silver solder, ensuring it is perfectly centred, perfectly level, and perfectly aligned so it will sit correctly and comfortably on the wearer’s cuff without any wobble. Once soldered, the joint is meticulously cleaned again and then polished to ensure a completely seamless finish, making it look as though the disc and the mechanism are one continuous, perfectly crafted piece of metal. This unwavering attention to detail at the assembly stage ensures that not only does the cufflink look fantastic from every angle, but it also functions flawlessly and will withstand years and years of fastening and unfastening, a true testament to its construction.

Finally, before any cufflink – or indeed any piece – leaves our workshop, it undergoes a rigorous, multi-point quality check performed by a different pair of expert eyes. We inspect every single aspect, under magnification: the clarity and crispness of the initial, the perfect evenness of the gold plating, the flawless smoothness of the polish, the security and fluid action of the mechanism, and the overall aesthetic appeal, looking for any minute imperfections. We look for microscopic flaws that a casual eye might miss, because we believe that true quality and excellence lie unequivocally in those hidden, minute details. Only when a piece meets our exceptionally high standards, a bar that we set incredibly high, is it lovingly cleaned one last time, carefully placed in its elegant, branded presentation box, and prepared for its journey to its new owner. It’s a moment of immense pride and quiet satisfaction for everyone involved, knowing that a piece of our passion, our meticulous craftsmanship, and our unwavering dedication is about to become a cherished part of someone else's treasured story.