That Warm Fuzzy Feeling: Where It All Begins

You know that feeling, don't you? That little shiver of excitement when you come across something truly special, something that just speaks to you. It’s a bit like finding a perfectly smooth pebble on a beach, or stumbling upon an old, forgotten photo that brings back a flood of memories. Here at The Handmade, we get that feeling all the time, especially when we are thinking about new creations, pieces that will one day carry stories of their own. There is a real magic in taking raw materials and transforming them into something that holds deep personal meaning, something that will be cherished not just for a few years, but for a lifetime, becoming a silent witness to countless moments. It is this very thought that often sets our hands in motion, especially when we start considering a robust piece, something that will truly stand the test of time, a piece like a Mens handmade silver band, designed to be a constant, comforting presence on a hand, through thick and thin. Every line drawn, every curve considered, it all starts with that intention, that desire for a piece to connect deeply with someone’s journey.

It is not just about the metal or the shape, you see; it is about the emotion it will carry, the promises it will represent, the everyday gestures it will be a part of. We spend a lot of time just thinking, chatting amongst ourselves about what makes a piece feel right. What makes it feel like it belongs? Sometimes it is the weight, sometimes it is the way the light catches a particular angle, and sometimes it is simply the comfortable feeling of it resting on your skin. We often talk about how our pieces are more than just jewellery; they are tiny anchors, beautiful little reminders of what matters most in life. Each item leaving our workshop carries a little bit of that magic, a little bit of the care and the good intentions that went into its making. It is a lovely thought, really, knowing that something we made with our own hands will be out there in the world, becoming a part of someone else’s story, a silent companion on their path.

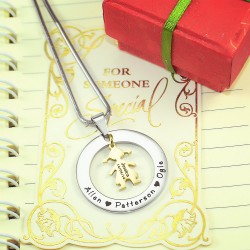

And speaking of meaning, when we select our materials, we are not just looking for the prettiest or the strongest. Oh no, it goes much deeper than that. We are thinking about where these materials come from, the journey they have taken before they even reach our benches. There is a certain pride in knowing that the very foundations of our creations are built on principles we truly believe in. For instance, when we craft a Fairtrade Gold Men's Wedding Ring, it is not just the beauty of the gold that we are focused on; it is the knowledge that every gram has been responsibly sourced, that the people involved in getting it out of the ground have been treated fairly, and that the environment has been respected. That sense of ethical responsibility, that connection to the wider world, it really adds another layer of warmth and integrity to the finished piece. It makes the gold glow a little brighter, don't you think?

This careful consideration of origins weaves its way into everything we create. It is a fundamental part of our ethos, a quiet promise embedded in every design. We often talk about the "soul" of a piece, and for us, that soul is intrinsically linked to its story from start to finish. From the moment the raw metal arrives, to the last polish and the final careful packaging, every stage is infused with a respect for the material and for the person who will eventually wear it. It is a continuous loop of care and attention, a commitment to crafting items that are not just lovely to look at, but that also carry a deeper, more meaningful narrative. We want our pieces to be enjoyed for many years, passed down through families, carrying tales of love and life within their metal, accumulating history with every passing season. That is the kind of legacy we are passionate about building, one small, thoughtfully made item at a time.

The Journey of a Material: From Earth to Our Hands

It always makes me chuckle a bit when someone comments on how simple a design looks. "Oh, it's just a bar," they might say about a necklace. But, oh dear, if only they knew the miles that particular metal has travelled and the hands it has passed through to become that seemingly simple shape. Take, for example, an It Is Well Bar Necklace. The smooth, clean lines, the perfect proportions – they are evidence of far more than just a quick snip and a polish. We spend a good deal of time ensuring that the silver we use, the very foundation of so many of our pieces, arrives at our workshop in its purest, most workable form. It is a meticulous process, this journey of material, a careful dance between nature and the various stages of refinement. We really do care about every step, ensuring the quality is top-notch, from the initial extraction to the point it becomes a gleaming sheet or wire, ready for us to begin our artistry.

Our metals come to us from trusted refiners, people who understand our commitment to ethical practices and uncompromising quality. We have built strong relationships with these people over the years, a real community of individuals who all contribute to the beauty you eventually hold in your hands. There is a lot of talk these days about where things come from, and rightly so. We have always felt that knowing the full story of our materials is absolutely vital. It is not just about being able to tell a good tale; it is about ensuring that every silver piece, every gold piece, has a clean conscience attached to it. From the moment the raw ore leaves the earth, through the complex processes of smelting, refining, and alloying, we keep a keen eye on the details, even when we are not directly involved in those early stages. It means the world to us to know that the foundations of our craft are as solid and reputable as the finished product itself.

Thinking about the final destination of a piece really helps shape our choices, doesn't it? When someone is looking for Custom Coordinates Bracelet Gift Ideas, they are often thinking about a significant place, a memory frozen in time. That emotional weight means the bracelet itself needs to be durable, comfortable, and beautifully crafted to last. So, when we are sourcing our silver, we are not just ordering a generic batch; we are considering its purity, its malleability, and its ability to hold a crisp, deep engraving for those precious coordinates. We want that piece to be worn daily, perhaps never taken off, becoming a true part of someone's life story. It is a constant consideration, this balance between the aesthetic and the practical, the beauty and the enduring strength required for everyday wear. Our selection process is genuinely rigorous because we know what these pieces mean to you.

The individuals and businesses we partner with are more than just suppliers; they are an extension of our own team, sharing our passion for quality and responsible practice. We are always chatting with them, learning about their own processes, making sure their standards align with ours. It is a bit like tending a garden; you choose your seeds carefully, you nurture the soil, and you watch over the growth. Our metal providers are the first step in that garden, ensuring we start with the very best seeds. They understand that a 0.7cm wide, 0.2cm thick band for a wedding ring needs to be absolutely perfect, without inclusions or weaknesses, because it is going to signify something monumental. This collaborative spirit, this shared dedication to excellence, ensures that the metals we use are not only beautiful but also ethically sound, providing a robust and pure canvas for all our creative endeavours. It is all part of the big picture, evidence of the care that goes into every single item that carries The Handmade name.

More Than Metal: The Heart of Every Item

When you slip on a pair of Silver personalised initial earrings, or any piece, really, you are not just putting on a bit of metal. You are wearing a promise of longevity, a tangible connection to a moment, a person, a memory. We pour so much into the design and creation process precisely because we know these items carry immense personal meaning. The quality of the silver, the way it has been treated, the finish we achieve – it all contributes to how long that promise will last, how well that connection will hold. We make sure our pieces are not just pretty for a day; they are made to endure, to age gracefully alongside you, gathering character and stories with every passing year. Think about it: a wedding band, for example, will be worn every single day, through washing up, gardening, working, celebrating. It needs to be tough, comfortable, and keep its good looks.

And caring for these items? It is surprisingly simple, really. Silver, being the lovely metal it is, sometimes likes a little polish to keep it gleaming, especially if it is been tucked away for a while. A soft cloth and a gentle jewellery cleaner are usually all you need to bring back its brilliant shine. We always say, treat your jewellery with a little love, and it will return that affection tenfold. Avoiding harsh chemicals and taking it off for really mucky tasks goes a long way, but honestly, our pieces are made to be lived in, not locked away in a box. They are designed for real life, for everyday adventures, for making memories. We want them to become a part of you, a comfort, a familiar friend that reminds you of all the good things. That is the true value, the lasting connection, that we hope to instil in every single item we send out from our workshop.

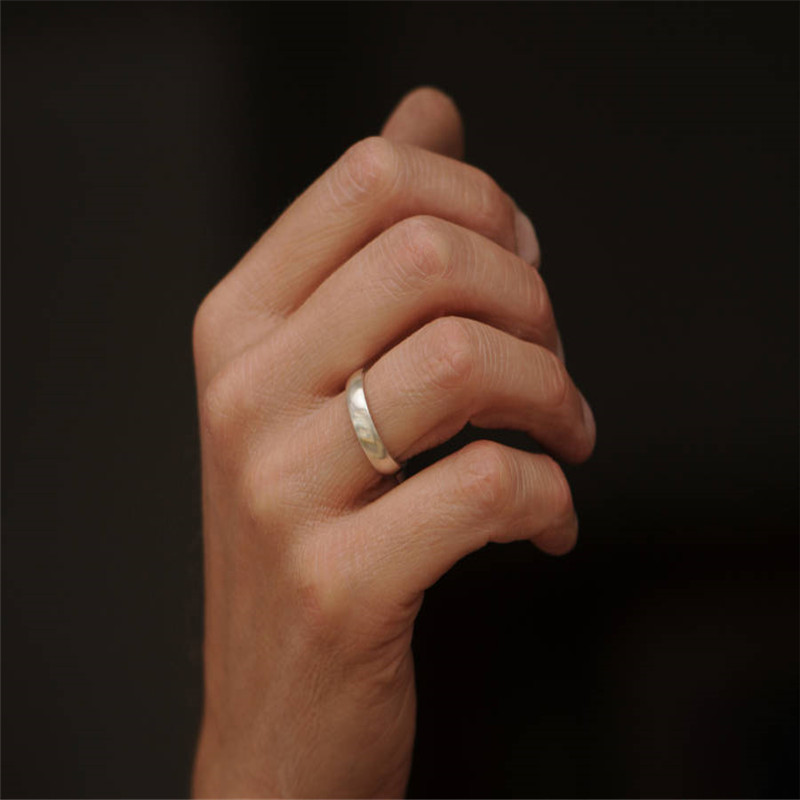

The feeling of a perfectly weighted piece, like a ring from our collection, is something truly special. When you Shop Handmade Gemstone Rings Today, you are choosing something crafted with immense care, something that marries the beauty of the earth's treasures with skilled hands. A ring is such a personal item, worn so close, always there, a tiny, silent companion. Its comfort, its balance, its sheer tactile pleasure, these are all things we consider from the very first sketch. We want it to feel like it belongs there, a natural extension of your hand, not something that feels foreign or cumbersome. The way a ring sits, the way it feels when you curl your fingers, the way it catches the light – these aren't accidents; they are the result of countless hours of refining and perfecting, ensuring that the piece becomes an extension of you, a cherished part of your everyday life.

Maintaining the beauty of these pieces, particularly a silver ring, is not a chore; it is an act of appreciation. Regular, gentle cleaning helps to ward off any tarnish that might naturally occur with silver exposed to the air. A quick buff with a polishing cloth can work wonders, bringing back that lovely lustre. Sometimes, a quick wash with mild soap and water, followed by a thorough drying, is all that is needed. For pieces with gemstones, a little extra care is required, naturally. It is about understanding the metal and the stones, giving them a little attention now and then so they can continue to tell their story brightly for generations. We really do make these things to last, you know. They are meant to be passed down, imbued with history and love, carrying the legacy of your life into the future. That is a pretty powerful thought, isn't it? To create something that outlives us, carrying our stories forward.

The First Spark: From Idea to Sketch

Every single item that comes to life here, no matter how small or seemingly straightforward, begins its journey with an idea, a little flicker of inspiration. Sometimes it is a feeling, sometimes it is a memory, and sometimes it is a specific request that gets the wheels turning. When we are designing a piece like our Mans Silver Wedding Band, which needs to be 0.7cm wide and 0.2cm thick, there is a tremendous amount of thought that goes into those precise measurements. It is not just about sketching a circle; it is about visualising how that band will feel on a finger, how it will look from every angle, and how it will withstand the rigours of daily life. Even something as playful as Personalised skeleton hand keyrings, with all their quirky charm, requires the same meticulous planning. We sketch, we redraw, we ponder, sometimes for hours, ensuring every proportion is just right, every detail considered, before we even touch a single piece of metal. It is the blueprint, the very foundation of what is to come, and getting it right at this stage saves so much heartache later on.

The initial design phase is a wonderfully creative, if sometimes frustrating, part of the process. We think about the ergonomics – how will the ring feel when you shake hands, or pick up a cup? We consider the aesthetic – will it look elegant, strong, subtle, or bold? For a 0.7cm wide band, there is a lovely substantial feel to it, a reassuring presence. And a 0.2cm thickness gives it enough strength without being overly chunky. These numbers are not pulled out of thin air; they are the result of years of experience, of understanding what works, what feels good, and what lasts. We might even make a few rough prototypes out of wax or copper just to get a real feel for the dimensions, to test the comfort and the visual impact. It is all about getting into the shoes of the person who will wear it, imagining their daily life, ensuring the design will slot seamlessly into their world. This detailed forethought is a bit like packing for a grand adventure; you want to make sure you have everything you need, and nothing you do not, for the journey ahead.

Getting Our Hands Dirty: The Metal's First Dance

Once the design is set, the real fun begins: getting our hands on the metal. This is where the magic truly starts to unfold. We take our carefully selected silver, which usually comes in sheets or wires, and begin to coax it into the desired form. For a ring, we often start with a flat sheet, which we then prepare for shaping. This often involves a process called annealing, where we heat the silver to a specific temperature and then let it cool. This makes the metal softer, more pliable, and much easier to work with without it cracking or becoming brittle. It is a bit like giving the metal a really good stretch before a big workout, getting it limber and ready for the transformation to come. Every piece, even something as complex as a Mother Tree Necklace, goes through this initial conditioning. This respectful handling of the material is absolutely key to ensuring the final product is not just beautiful, but structurally sound and incredibly durable.

Then comes the meticulous work of getting the dimensions just right. For our 0.7cm wide and 0.2cm thick band, we will carefully mark out the exact strip of silver we need from the annealed sheet. Precision is everything here. We use finely calibrated tools, not just for cutting, but for rolling and drawing the metal to achieve that perfect thickness and width. It is a slow, steady process, often involving multiple passes through a rolling mill, each time reducing the thickness incrementally, until we hit that sweet spot of 0.2cm. It is amazing how much a tiny fraction of a millimetre can change the feel and the look of a piece. Too thin, and it feels flimsy; too thick, and it is cumbersome. Finding that perfect balance, that 'just right' feeling, is what we aim for. This stage requires immense patience and an incredibly steady hand, as any deviation here would mean starting all over again, or worse, compromising the integrity of the finished ring.

The Ring Takes Shape: Bending and Joining

With the strip of silver perfectly prepared to the right width and thickness, the next step is to bend it into a circle. This is a wonderfully satisfying part of the process, watching a flat piece of metal begin to take on the familiar form of a ring. We use specialized ring-bending pliers or a forming block, applying gentle, even pressure to gradually curve the silver. It is not something you rush; you have to feel the metal, understand its resistance, and guide it carefully. The aim is to create a perfect circle, with the two ends meeting seamlessly. This is where the magic really starts to happen, transforming a strip into a symbol of eternity. It is the same kind of careful shaping we do for a Silver name bracelet, ensuring that every curve is fluid and flawless, allowing the metal to wrap comfortably around the wrist. The attention to detail at this point dictates how well the final ring will sit on the finger, how truly comfortable it will feel for its wearer.

Once the circle is formed and the ends meet snugly, it is time for soldering. This is a vital step, essentially welding the two ends together to create a continuous, unbroken band. We carefully paint a tiny amount of flux onto the join – a magical substance that helps the solder flow – and place a small pallion of silver solder right where the ends meet. Then, with a jeweller's torch, we apply heat. It is a delicate dance with the flame; too little heat, and the solder will not flow properly; too much, and you risk melting the entire ring! You watch the metal intently, waiting for that precise moment when the solder melts and flows into the join, creating an invisible bond. The entire workshop holds its breath, just for a second, waiting for that perfect fusion. It is a moment of pure satisfaction when you see the silver come together as one, strong and unified, ready for its next transformation. The integrity of this join is absolutely essential; it is what gives the ring its strength and ensures it will last for decades.

The Nitty-Gritty: Shaping, Smoothing, and Refining

After the solder has cooled and been 'pickled' in a mild acid solution to clean off any firescale, the ring looks a bit rough around the edges, not quite the gleaming beauty you would expect. This is where the real artistry of refining comes into play. The first task is to file down any excess solder and true up the shape of the band. We use a variety of files, from coarse to very fine, carefully working the surface to remove any imperfections, ensuring the 0.7cm width is consistent all the way around, and that the 0.2cm thickness remains uniform. It is a slow, methodical process, requiring a keen eye and a steady hand, constantly checking the shape against our mandrels to ensure it is perfectly round and the correct size. Even for something like a Graduation Monogram Necklace, where crisp edges are vital, this level of detailed filing is absolutely essential. The aim is to make the join completely disappear, as if the ring was forged from a single, unbroken piece of silver. This stage really separates the merely made from the truly crafted, creating a smooth, inviting canvas for the final finish.

Once the basic shape is perfect, we move onto the sanding stage. This involves using progressively finer grades of abrasive papers, starting with something quite coarse to remove any file marks, and gradually moving to super-fine grits that feel almost like soft paper. Each stage removes the scratches from the previous one, slowly refining the surface until it is incredibly smooth to the touch. It is a bit like preparing a canvas for a painting; you want it absolutely pristine before you apply the colour. This process is particularly important for a ring that will be worn every day, as any rough spots would be uncomfortable. We work our way around the inside and outside of the band, paying close attention to the edges, ensuring they are gently rounded for comfort, but still hold their defined form. This stage is where the ring really starts to feel lovely in the hand, moving from a raw piece of metal to something genuinely tactile and pleasing.

Finally, we reach the polishing stage, and this is where the silver truly comes alive, revealing its inherent lustre. We use a series of polishing compounds, applied to spinning mops on a polishing motor. Again, we start with a coarser compound to get rid of any lingering fine scratches, and then move to an ultra-fine compound that brings out that mirror-like shine we are known for. It is a messy job, involving lots of black polishing compound dust, but the results are always incredibly satisfying. Each pass over the mop brings more and more brilliance, transforming the dull metal into a gleaming masterpiece. We meticulously polish every surface, inside and out, making sure every inch of that 0.7cm wide, 0.2cm thick band reflects the light beautifully, catching every glint. The dedication at this stage is all about making the ring feel as smooth as glass and look utterly captivating, a true pleasure to behold from every angle, promising a long-lasting, radiant finish for its future owner.

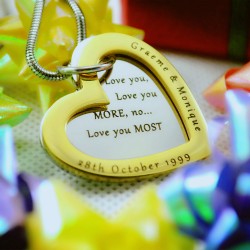

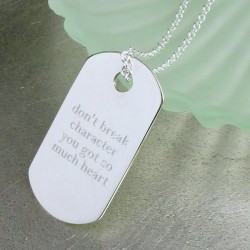

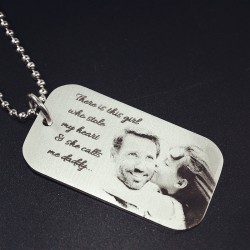

After all that polishing, each ring gets a thorough ultrasonic clean to remove any remaining polishing compounds, followed by a steam clean to ensure it is sparkling clean and utterly pristine. Then comes the final inspection, a critical stage where we examine the ring under magnification, looking for any tiny imperfections, any stray scratches, any unevenness in the surface. We are incredibly picky at this point, because we understand this ring is going to be a symbol, a cherished item for a lifetime, and it needs to be absolutely perfect in every single detail. Sometimes, a customer might request an inscription – a date, initials, a meaningful word, or perhaps a secret message. This is done with a precision laser engraver, ensuring a crisp, lasting mark inside the band, adding that truly personal touch without compromising the structural integrity of the silver. It is the very last step in a long, careful process, where every single detail has been considered, every touch applied with dedication, all to ensure that the finished ring is not just an object, but a treasure, ready to embark on its own unique journey with its new owner. The whole workshop gathers around for the final 'oohs' and 'aahs', often sharing a cuppa as we admire the completed piece. There is a real sense of accomplishment, a quiet satisfaction knowing that we've poured our heart into something that will mean the world to someone else.