From a Spark to a Sketch: Dreaming Up Your Design

Isn't it funny how sometimes the most treasured things in life start with just a flicker, a tiny idea, a 'what if'? I often find myself pondering this whilst I'm sat at my workbench, a quiet hum of creativity in the air, surrounded by the beautiful chaos of tools and materials. There’s a particular kind of magic that unfolds when someone approaches us with a vision for something truly their own, a piece that whispers their story, a piece they've dreamt into being. It’s a wonderful privilege, really, getting to be part of that journey, seeing that initial spark catch fire.

It's not every day you get to craft something so utterly personal, something that will live and breathe with its owner, collecting memories and stories along the way. We get a real kick out of those moments, you know, when a customer's eyes light up as they describe what they're after. It could be something as grand as a statement piece, or as subtle as a tiny, hidden detail. Each request is a puzzle, a delightful challenge that we absolutely adore taking on, especially when it comes to something as versatile and expressive as a bracelet designed entirely by you, for you.

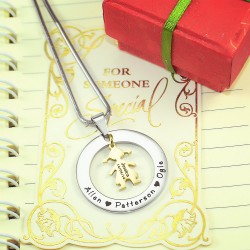

You see, making something truly yours, like our MADE BRACELET - And IN OWN DESIGN, isn't just about picking a style from a catalogue. Oh no, it's so much more! It’s about diving headfirst into what makes *you* tick, what symbols resonate with your heart, what colours dance in your mind. The process of bringing a customer's unique vision to life, shaping it with our hands, often starts with a simple chat. We might talk about something they saw, a feeling they want to capture, or perhaps even the desire to complement another treasured item, like a Unique Handmade Patterned Silver Band they already wear, creating a cohesive story across their jewellery collection. It’s all part of the fun, the collaborative dance that leads to something truly magnificent.

Sometimes, the inspiration for a new piece comes from the most unexpected places. I was having a cuppa the other day, watching the way the light played on a dew-kissed spiderweb in the garden – all those tiny, intricate patterns, each strand placed with such delicate precision. It made me think about the beauty of structure and how we can translate such natural artistry into metal. That’s the sort of quiet observation that often fuels a fresh approach to a design. It's those little moments of inspiration that keep the creative wellspring flowing, ensuring that every piece we craft, especially a bespoke bracelet, carries a piece of that unique thoughtful energy.

There's a fantastic sense of satisfaction that comes from sitting down with a customer, pencil and paper in hand, just sketching out ideas. We talk about their life, their passions, the people who mean the world to them. It's about capturing a moment, a memory, or an aspiration in a tangible form. For example, when someone is looking for a Personalized Silver Engagement Ring, we discuss not just the design, but the love story behind it, what makes their connection unique. It’s the same deep dive into personal meaning when we embark on creating a custom bracelet. It’s a relationship built on trust and shared excitement.

One chap recently wanted a bracelet that subtly referenced his love for hiking, without being overt. We chatted about mountain contours, the texture of rough rock, the way paths wind. Slowly but surely, through a series of sketches and discussions, we landed on a design that incorporated a subtle, undulating pattern, almost like a topographical map, on a smooth, comfortable band. It was a beautiful process, watching his idea solidify into something real. That’s the core of what we do here at The Handmade; we translate feelings and stories into wearable art, giving each custom piece a soul, a secret language only its wearer truly understands.

Sourcing the Shine: The Journey of Our Materials

Now, whilst the initial spark of an idea is absolutely crucial, the very foundation of any magnificent piece of jewellery, especially a custom-designed bracelet, lies firmly in the quality of its materials. We're incredibly particular about where we source our precious metals and other components. It’s a meticulous process, a journey that begins long before a single piece of metal ever enters our cosy workshop. We're talking about building relationships, trust, and a shared commitment to ethical practices and exceptional standards, because frankly, our customers deserve nothing less.

For something as special as a MADE BRACELET - And IN OWN DESIGN, the gold or silver we use has its own fascinating story. It doesn’t just magically appear on our workbench, gleaming and ready to be shaped. Oh no, it goes on quite a trek! We work with established, reputable suppliers who are as passionate about responsible sourcing as we are. They ensure their metals come from places where environmental impact is carefully considered, and where fair labour practices are a given. This means we're able to trace the lineage of our materials, giving us, and in turn, you, that comforting peace of mind. It’s a whole network of trusted hands, from the refiners who purify the metals to the rolling mills that turn them into the sheets and wires we use every day, ready to become a beautiful Shop stackable initial gold ring, or indeed, your unique bracelet.

When it comes to the sheer variety of materials we need for all the wonderful bits and bobs we create, it's quite a logistical ballet, I must say. Beyond the classic silver and gold, we're always on the lookout for other interesting elements, like the specific alloys that give rose gold its blush, or the robust, modern materials we might use for more masculine pieces. We hold ourselves to really high standards, meaning we only ever select the best. Every batch of metal, every clasp, every little finding gets a thorough inspection upon arrival. It’s about ensuring that the purity is spot on and that the integrity of the material is faultless, because nobody wants a lovely piece to let them down down the line, do they?

Take, for instance, the subtle blush of our rose gold, so popular for items like Rose gold state necklaces. Achieving that perfect hue, that warmth, is down to a precise blend of gold, copper, and sometimes a tiny hint of silver. Our suppliers are masters of these alloys, ensuring consistency and a beautiful, enduring colour that won't fade. It’s not just about the colour, though; it’s about the workability of the metal, how it responds to our tools, how it polishes, and how it holds its shape. These are all considerations that go into our rigorous selection process, ensuring every material is a joy to work with.

The complexity of our supply chain management might not be the most glamorous part of what we do, but believe me, it’s absolutely vital. We’re constantly in touch with our network of suppliers, discussing lead times, checking specifications, and anticipating future needs. For a bespoke piece, the timing is often critical. We need to know that if a particular gauge of silver sheet is required for a MADE BRACELET - And IN OWN DESIGN, it will be here precisely when we need it. This meticulous planning prevents delays and ensures that we can deliver on our promises, bringing your personalised jewellery to life within the agreed timeframe. It's a testament to the dedication of many skilled individuals, all working together, even behind the scenes, to make these beautiful objects possible.

Product Value & Emotional Resonance: A Story on Your Wrist

So, you’ve got this brilliant idea for a MADE BRACELET - And IN OWN DESIGN, and we’ve sorted out the very best materials. But what truly makes a piece like this special? It's not just the gleam of the metal or the cleverness of the design, although those are certainly big parts of it. No, the real magic, the lasting value, comes from the story it tells, the connection it forges, and the feelings it evokes every single time you slip it on. That’s the emotional resonance we strive for, that deep, personal connection that transforms a lovely object into a cherished heirloom.

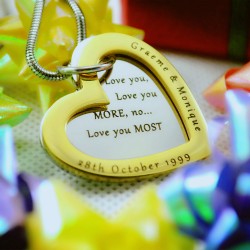

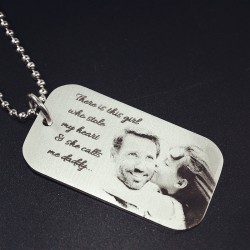

Think about it: when you wear something that you helped bring to life, something that holds a personal message or a significant date, it becomes so much more than just an accessory. It's a constant, comforting presence, a little whisper of what’s important to you. It might be a reminder of a special person, a milestone achieved, or even a personal motto that keeps you going. We see this all the time with pieces like Handmade men's ceramic tungsten rings, where the robust material and custom engraving speak volumes about a person's character and journey. A custom bracelet from us holds that same incredible power, a unique piece of your own narrative, beautifully crafted to stand the test of time.

One of the loveliest aspects of creating a MADE BRACELET - And IN OWN DESIGN is the sheer individuality of it all. No two pieces are ever truly identical, because no two stories are ever the same. Each curve, each tiny detail, each finish reflects a unique personality. This isn’t about mass production; it's about celebrating the distinctiveness of you. This means that your bracelet isn't just something you wear; it's a part of you, an extension of your character, and a conversation starter, often leading to wonderful exchanges about the inspiration behind it. It's truly fulfilling to witness how people connect with their custom creations, how those pieces become woven into the fabric of their daily lives.

Of course, for such a meaningful piece to truly stand the test of time, a little bit of tender loving care goes a long way. You know, something we often chat about with our lovely customers is how to keep their treasures looking tip-top. A MADE BRACELET - And IN OWN DESIGN, like any cherished item, benefits from a little pampering now and then. Whilst commercial jewellery cleaning solutions do a decent job, and they generally contain ammonia and water as their main ingredients, you might be surprised to find that you can easily make your own jewellery cleaning solution at home, and you will be pleasantly surprised with the results. It's a simpler, cheaper route that many of our customers prefer for a quick spruce up.

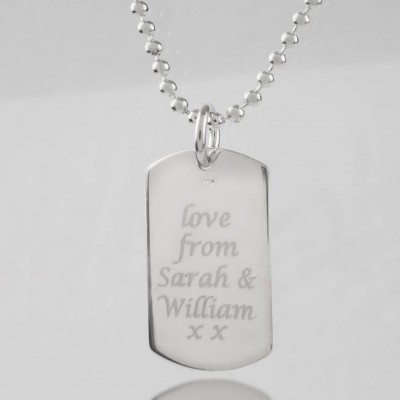

To whip up your own solution, you just need a few bits and bobs you probably already have lying around: some warm water, a squirt of mild dish soap, and perhaps a tiny splash of ammonia if you’re feeling adventurous (though be careful with ammonia on certain gemstones, always check first!). A soft toothbrush is a great tool for gently scrubbing away any grime. Simply let your bracelet soak for a few minutes, give it a gentle brush, rinse it thoroughly under cool water, and then polish it dry with a soft, lint-free cloth. This little routine keeps your Handmade message dog tag necklace or any other custom piece sparkling, ensuring that its shine continues to reflect the memories it holds for years and years to come, truly keeping its emotional value alive.

From a Spark to a Sketch: Dreaming Up Your Design

Every piece we create, especially a custom one like our MADE BRACELET - And IN OWN DESIGN, begins as an idea, sometimes a fully formed vision, sometimes just a tiny seed of thought. My favourite part of this initial stage is the collaborative chat, the friendly back-and-forth where we explore all the possibilities. We'll grab a cuppa, perhaps even a biscuit or two, and just talk. We’ll delve into what kind of style someone has, what their daily life looks like, what they want their bracelet to say. It's not about being pushy, it’s about listening, really listening, to what’s being dreamt up.

We might look at examples, not to copy, but to get a feel for preferences. Do they like bold and chunky, or subtle and delicate? High polish or a matte finish? Are there specific motifs or symbols that hold meaning for them? We’ll sketch a few rough ideas, playing with different shapes and sizes, seeing what feels right. Sometimes, it takes a few tries, a bit of tweaking here and there, until that 'aha!' moment happens and we know we've nailed it. It’s like being a detective, piecing together clues to form the perfect picture, ensuring that the Shop Men's Handmade Monogrammed Cufflinks, or indeed, the custom bracelet, truly captures the essence of the wearer.

This early design stage is critical, laying the groundwork for everything that follows. A well-thought-out design ensures that the final piece will not only look fantastic but also be comfortable to wear and durable enough to last. We're thinking ahead at this point about how the metal will behave, what tools we'll need, and how the various components will come together seamlessly. It’s a bit like an architect drawing up plans, ensuring every beam and every corner is perfectly aligned, even for a piece as seemingly simple as a beautifully crafted bangle. This careful planning avoids headaches down the line and means we can focus purely on the artistry when we get to the workbench.

The Workshop's Warm-Up: Preparing Our Canvas

Once we have that lovely design sketch agreed upon, it’s time to head into the workshop. This is where the magic truly starts to take shape, where raw materials begin their journey towards becoming something precious. First up, we carefully select the right gauge and type of metal. For a MADE BRACELET - And IN OWN DESIGN, this choice is fundamental; a delicate chain needs a fine wire, whilst a sturdy cuff will require a thicker sheet. It’s about balance and ensuring the finished piece has both strength and elegance. We weigh out exactly what’s needed, being incredibly precise – no wastage here!

Then comes the annealing process, which sounds rather fancy but is essentially about softening the metal. Silver and gold, when worked, become harder and more brittle. To prevent them from cracking or snapping as we bend and shape them, we heat them gently with a jeweller’s torch until they glow a soft, cherry red (for silver) or until the flame appears green (for gold), and then we quench them in water. This returns the metal to a pliable state, ready to be transformed. It's a bit like giving the metal a relaxing spa treatment before it undergoes its transformation, ensuring it’s ready for the intricate work of crafting a Dainty Friendship Necklace, or your very own bespoke bracelet.

After annealing, the metal needs to be cleaned of any firescale, which is that dull, discoloured layer that forms during heating. We pop it into a warm pickling solution – a mild acid bath – which gently removes the firescale, leaving the metal bright and ready. It’s a necessary step to ensure a clean, smooth surface for all the subsequent filing, shaping, and polishing. Each step, no matter how small, plays a crucial role in the overall quality and aesthetic of the final piece. We’re incredibly particular about these preparatory stages, as they truly lay the foundation for a stunning finish.

Metal's Metamorphosis: Hammer, Heat, and Heart

Right, now we’re really getting into the thick of it! With our metal softened and gleaming, it’s time to start the actual crafting of your MADE BRACELET - And IN OWN DESIGN. This stage is all about precision, patience, and a healthy dose of elbow grease. For a bracelet, we might begin by taking a flat sheet of metal and carefully marking out the outline of the design. This isn't a job for shaky hands, let me tell you! Every line must be precise, every curve smooth, because even a tiny wobble at this stage will show up glaringly later on.

Once the shape is marked, we start cutting. Depending on the complexity, this could involve a jeweller’s saw – a tiny, incredibly fine blade that allows us to cut intricate patterns with surprising accuracy. Watching the blade dance through the metal, creating delicate filigree or bold outlines, is truly mesmerising. For heavier gauge metal, we might use shears. After cutting, the edges are always a bit rough, so a meticulous filing process begins. We smooth every single edge, removing any burrs, ensuring the piece is comfortable against the skin and that the lines are crisp and clean, whether we're crafting a Custom Coordinates GPS Necklace or a custom bracelet.

Then comes the forming. For a cuff bracelet, this might involve carefully hammering the flat metal over a triblet or mandrel – a tapered steel form – gradually coaxing it into a curved shape. This takes a gentle touch, a steady hand, and an understanding of how the metal wants to move. It’s a rhythmic process, the tap-tap-tap of the hammer, slowly transforming a flat sheet into a three-dimensional object. If the design calls for links, we meticulously cut, form, and solder each one, ensuring they move fluidly and lie perfectly. Soldering, of course, is an art in itself, requiring just the right amount of heat and solder to create a strong, invisible join, making the piece feel like one continuous, flowing form.

Finishing Touches: The Gentle Art of Perfecting

Once the main structure of the MADE BRACELET - And IN OWN DESIGN is complete, it's time for the finishing touches – and this is where true craftsmanship really shines through. This stage involves a series of increasingly fine sanding and polishing steps, transforming a somewhat dull, scratched piece of metal into a gleaming, reflective work of art. We start with coarser abrasive papers, gradually working our way up to incredibly fine grits, meticulously removing every scratch, every tiny imperfection. It’s a painstaking process, but absolutely essential for that flawless, mirror-like finish that everyone admires.

After the sanding, the piece moves to the polishing wheels. We use various wheels, each loaded with a different polishing compound, from a rough cutting compound to a super-fine, high-gloss polish. It’s all done by hand, holding the bracelet against the whirring wheel with just the right amount of pressure, ensuring an even shine across every surface. This stage is incredibly satisfying, watching the metal come alive under our touch, its true beauty finally revealed. The room fills with the faint scent of polishing compound and a soft hum from the motor, whilst the metal transforms, taking on a brilliant lustre. This is the stage where the piece truly begins to sing, ready to become a Custom made handmade bracelet design that catches every eye.

Sometimes, a design might call for a different finish – perhaps a brushed, matte look, or an oxidised, antiqued effect. In these cases, we adapt our finishing process. For a brushed finish, we’ll use special brushes or textured pads to create uniform, subtle lines across the surface, giving the metal a soft, understated glow. For an oxidised look, we might apply a chemical solution that darkens the recesses of the metal, highlighting the texture and giving the piece an aged, rustic charm. Each finish requires its own specific techniques and a keen eye to achieve perfection, ensuring the bracelet embodies the exact aesthetic envisioned during those initial design chats.

Engraving & Embellishment: Tales on Your Wrist

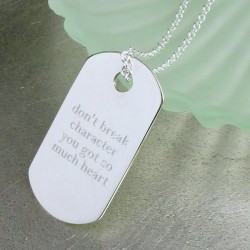

Now, this is where your MADE BRACELET - And IN OWN DESIGN truly becomes *yours*, in every sense of the word. After all the careful shaping and polishing, it’s time to add those deeply personal touches – the engraving, the tiny embellishments that tell your unique story. Whether it's a significant date, a loved one's initials, a secret message, or a delicate symbol, these details transform a beautiful object into an incredibly meaningful keepsake. We take immense pride in this part of the process, knowing that each inscription carries a weight of emotion and personal history.

For engraving, we have a few methods at our disposal, depending on the desired effect. For very fine, intricate details, or specific fonts, we might use a laser engraver, which offers incredible precision and allows for highly detailed designs. For a more traditional, deeply hand-carved look, we often turn to our trusty hand gravers. This requires immense skill and a steady hand, as each stroke of the tool meticulously removes a tiny sliver of metal, creating a sharp, lasting impression. The choice of method depends entirely on the design and the customer's preference, always ensuring the message is clear, legible, and beautifully executed, whether it's for a cherished bracelet or a unique pendant.

Beyond engraving, there might be other embellishments to add. Perhaps a tiny, flush-set gemstone to mark a birth month, or a delicately applied texture that mimics a natural pattern. These small additions require an equal amount of precision and care. Setting a tiny stone, for example, involves carefully preparing a seat for it, securing it perfectly so it catches the light, yet remains completely safe and secure within its setting. It’s all about those micro-details that often go unnoticed to the casual observer, but contribute so much to the overall feel and integrity of the piece. These are the secrets, the hidden efforts, that make a piece truly special, a silent testament to the passion poured into its creation.

The Grand Finale: Quality Checks and Tender Care

As your MADE BRACELET - And IN OWN DESIGN nears completion, it undergoes a series of rigorous quality checks. We don’t just wave a magic wand and call it done; oh no, every single aspect of the piece is scrutinised with an almost obsessive attention to detail. I’ll personally inspect every curve, every join, every surface under magnification, searching for the tiniest imperfection that might have escaped earlier stages. Is the clasp perfectly secure? Are all the edges buttery smooth? Is the engraving crisp and perfectly aligned? It's a final, thorough examination to ensure that what leaves our workshop is nothing short of perfection.

We'll also give it one last clean, a final polish, ensuring it arrives at your doorstep absolutely gleaming, ready to be worn and cherished. Packaging is also an important part of the experience. Each custom bracelet is carefully nestled in one of our signature presentation boxes, protecting it during transit and making the unboxing experience feel truly special. It’s more than just a box; it’s the final flourish, the presentation of a piece that has been crafted with so much thought, skill, and heart. We even include a little care guide, reminding you of those simple at-home cleaning tips we discussed, to keep your new treasure sparkling for years.

The moment a finished MADE BRACELET - And IN OWN DESIGN leaves our workshop is always a mixture of pride and a little bittersweetness. Pride, of course, in the beautiful object we’ve helped bring to life, knowing it’s going to make someone very happy. Bittersweet, because we’ve spent so much time with it, nurturing it from concept to completion, and now it’s off on its own adventure. But that’s the joy of it, isn’t it? Knowing that a piece of our passion and skill is out there in the world, becoming a part of someone else’s story, carrying meaning, and perhaps even inspiring a few smiles along the way. That’s why we do what we do, and we absolutely wouldn’t have it any other way.