That Feeling When Things Just Click into Place

You know, there are days in the workshop where everything just flows. The ideas, the tools, the materials – it’s as if the universe is nudging you along, saying, “Yes, this is it, mate!” Sometimes it’s the sparkle of a new gemstone catching the morning light, inspiring something truly whimsical and wonderful, like how a particular design came about, almost like a Stone Beehive Bloom Ring, all intricate and delicate. Other times, it’s the satisfying weight of a metal in your hand, a promise of something substantial and lasting.

It’s a peculiar kind of magic, really. It’s not about grand gestures or flashy theatrics; it’s about the quiet hum of the machinery, the focused silence, the tiny adjustments, and the immense satisfaction of watching a raw idea slowly, surely, take physical form. This particular creative current often starts with a single thought: how do we make something not just beautiful, but truly meaningful and built to last? How do we craft a piece that tells a story of strength and quiet confidence, something that feels utterly right, both in your hand and on your person, day in and day out? This thought has been buzzing around my head a lot lately, especially when we talk about pieces destined for daily wear, items that become part of someone's own daily narrative. We don't just put things together; we craft companions.

That particular current of thought led me down a path, a rather sturdy and unyielding one, straight to the heart of what makes our Men's Tungsten Ring so darn special. You see, it’s a story about resilience, about understated sophistication, and about choosing materials that stand up to the hustle and bustle of life. We wanted to create something for folks who appreciate strength, durability, and a clean, sharp look, but also something that carries a personal touch. Something that feels robust and dependable, but never shouts for attention, preferring to exude a quiet confidence instead. It's the kind of piece that settles comfortably into your daily rhythm, becoming an extension of you without even trying. That's the essence of it, really – crafting pieces that feel like they were always meant to be with you.

The Journey from the Earth to Our Workbench

Right, so let's chat about where the magic really begins: the materials themselves. For a piece like our tungsten ring, it all starts long before it ever lands on my bench. We’re talking about tungsten, one of the hardest metals on Earth, and some rather snazzy black carbon fibre. Getting these bits and bobs to our workshop isn't as simple as nipping down to the local hardware shop, believe me. We put in a fair bit of legwork, making sure every single component meets our incredibly high standards. Think of it as a treasure hunt, but with far more paperwork and quality checks!

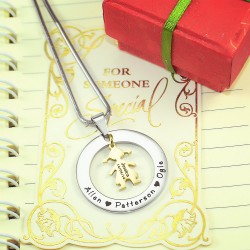

We work really closely with a few select suppliers, folks who genuinely get what we're about. When we’re sourcing, say, the raw silver for our Handmade silver initial pendants, or indeed the tough-as-nails tungsten, we’re not just looking at the price tag. Oh no, it goes way beyond that. We’re digging deep into their practices, making sure their operations are sound, responsible, and that they share our dedication to quality. It’s about building relationships based on trust and a shared understanding of what makes a piece truly special, right from its very beginnings, ensuring everything is above board and ethically sourced. This commitment to the provenance of our materials is something we take very seriously, because we believe the story of a piece starts with the story of its components.

The journey for the tungsten, for example, is quite fascinating. It starts as an ore, deep in the earth, then goes through a rather involved purification process to become the incredibly dense, strong metal we use. Each batch arriving at our workshop is accompanied by a host of certifications, confirming its purity and composition. We verify these details ourselves too, because while trust is great, a bit of independent checking is always a smart move. It’s a meticulous dance of checks and balances, ensuring that when we say 'one of the hardest metals on Earth,' we really mean it. This unwavering attention to detail ensures that the strength and durability we promise you are genuinely there, baked into the very core of the material. This thoroughness is a testament to how seriously we take every single element that goes into our creations.

Then there's the carbon fibre. This isn't just any old black stuff. It's carefully woven, almost like a textile, but made of unbelievably strong, thin strands of carbon. We need it to be perfectly uniform, with no flaws, because it’s going to be a striking feature right in the middle of that tough tungsten band. The way it catches the light, the subtle pattern – it's all down to the quality of that initial weave. We scrutinise every roll, every sheet, ensuring it's absolutely spot on, because that beautiful inlay needs to be as robust and flawless as the metal around it. It's a bit like picking out the perfect fabric for a bespoke suit; every thread counts. This fastidiousness guarantees the finished piece will possess that seamless blend of toughness and refined appearance we strive for, making sure that even the smallest detail contributes to the overall integrity and beauty of the ring.

The Heart of the Matter: Why Our Rings Are More Than Just Metal

So, we've got our incredible materials, carefully chosen and prepared. Now, what makes this specific ring, the Men's Black Carbon Fiber Inlay Polished Tungsten Ring, truly stand out? Well, for starters, there's that impressive 7mm width. It's substantial without being overly bulky, giving it a really confident presence on the hand. It's a statement, yes, but a sophisticated, quiet one. Then, obviously, there's the tungsten itself. We often chat about how much we adore creating pieces with deep personal meaning, like a Silver Hearts Necklace for a loved one, but there's also a deep satisfaction in crafting something that simply feels incredibly robust and dependable in its own right.

Tungsten, as I've mentioned, is an absolute beast when it comes to hardness. It's scratch-resistant to a fault, meaning it will hold its polished shine for a very, very long time. This isn’t just about looking good; it’s about enduring. It’s about a piece of jewellery that can handle daily life, whether you’re shaking hands, working at a desk, or just going about your day. It’s a material that laughs in the face of minor bumps and scrapes, retaining its pristine appearance with very little fuss from you, which is always a bonus, isn't it?

And let's not forget that black carbon fibre inlay, running right there on the centre of the band. It adds this incredible contrast – the deep, almost mysterious black against the sleek, polished grey of the tungsten. It gives the ring a modern, almost architectural feel. It’s a touch of contemporary flair, a bit of texture and visual interest that elevates the whole design. Plus, carbon fibre is also incredibly strong and lightweight, so it complements the tungsten perfectly. It’s a clever pairing, if I do say so myself, offering both aesthetic appeal and a continuation of the ring's inherent durability story. The thoughtful integration of these materials ensures a piece that feels both cutting-edge and timeless, a true reflection of the wearer's discerning taste.

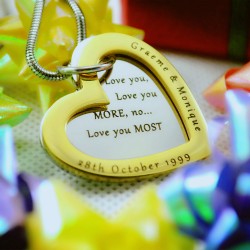

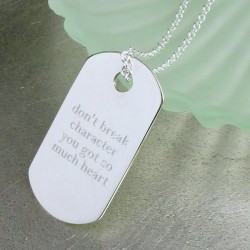

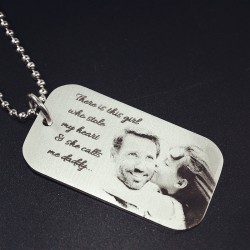

Now, about making it truly 'yours'. We offer custom engraving on the base of the ring. This is where it gets really personal, doesn't it? A date, initials, a little secret message – it transforms a fantastic piece of jewellery into something uniquely meaningful. It's a little whisper between you and the ring, a story only you need to know. That's the beauty of it, adding that little extra layer of sentiment that makes it far more than just metal and fibre. It's a personal touch that genuinely changes everything. It turns a beautiful item into a cherished keepsake, a tangible representation of memories or affections that last as long as the ring itself, which, for tungsten, is a really, really long time. We know that these small, personal additions, like those on a Handmade Silver Circle Initial Necklace, are what often make a piece truly unforgettable for the person wearing it.

A little heads-up though, and this is super important: because of tungsten's incredible hardness, we cannot offer any resizing on this ring. Nope, not even a tiny bit. This means getting the size spot-on from the get-go is absolutely key. We really, really want you to have a perfect fit, so we've got some brilliant tools to help you out. We’ve got a detailed ring size comparison table, covering various countries, because nobody wants a ring that's too loose or too snug. We also have a handy Sizing Tool PDF that you can print out at home. You can either pop an existing ring onto the circles to find its match, or snip out the measuring bar to wrap around your finger. We even suggest doing both methods, just to be extra, extra sure. It's all about making sure that your ring fits like a dream right from the very first moment you slip it on, ensuring that happy sigh of perfect fit. This thoroughness in helping you find the right size is part of our commitment to ensuring every customer's satisfaction, making sure that your Heart infinity ring jewelry, or any other piece, fits you just right.

Oh, and on a slightly different note, but speaking of materials and ensuring you get the real deal, I just wanted to share a little tip that's generally good to know when you're thinking about other pieces, perhaps with stones. For instance, with turquoise, it’s always a smart idea to give it a proper once-over. You want to see uniform colour throughout, and it should feel more opaque than clear. Little veins or splotches, from white to black, are usually a good sign of genuine turquoise, not a fake. Most importantly, always buy from a reputable place and don't be shy about asking for written proof of its value. Honestly, with all the clever enhancements out there for imitation stones, it can be a real head-scratcher trying to tell the difference. It's a little bit like the detective work we do with our own materials, ensuring authenticity and quality. This applies to so many aspects of jewellery, making sure you always get what you expect and deserve.

From Rough Idea to Polished Perfection: A Peek Behind the Curtain

Setting the Scene: Our Creative Space

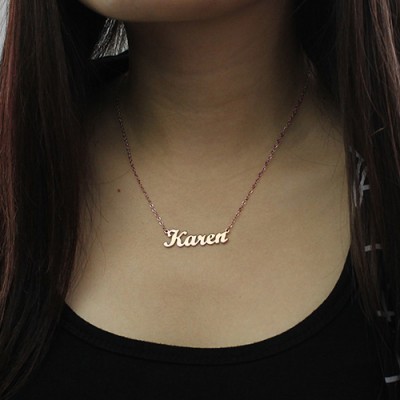

Every piece we make starts with an idea, but then it needs the perfect home to grow into something real. Our workshop is precisely that – a creative hub, brimming with specialised tools and a very particular kind of organised chaos. Before a single piece of tungsten even touches a machine, the space is prepared. It's about more than just tidying up; it's about setting the right mental stage. We clean the benches, check the air filtration (no tiny dust particles for us, thank you very much!), and ensure every tool is where it should be, sharp and ready. This isn’t just for efficiency; it’s about respect for the process, respect for the materials, and respect for the person who will eventually wear the ring. It’s a quiet ritual that prepares us for the precise work ahead, creating the atmosphere where focus and precision can truly thrive, like tending a delicate Rose Gold Karen Name Necklace, ensuring every detail is just so.

Working with tungsten is a whole different kettle of fish compared to, say, silver or gold. It's unbelievably hard, which is brilliant for durability, but it means you can't just bend it or reshape it like softer metals. This means our initial preparation has to be absolutely meticulous. The raw tungsten arrives in pre-formed blanks, closer to the final ring shape. Our job is to refine these, ensuring the dimensions are utterly spot-on. We’re talking about measurements down to a fraction of a millimetre, because once you start working it, there’s no going back. Precision cutting and grinding are the order of the day, using specialist diamond-tipped tools that can actually make a dent in this formidable material. It's a careful dance, ensuring the initial form is perfect before we move on to the next delicate stage. This preparatory work is absolutely foundational; any misstep here would mean starting all over again, and nobody wants that!

The Carbon Fibre Interlude: Weaving in the Dark

Once the tungsten band is shaped to perfection, we create the channel for the carbon fibre inlay. This isn't just a simple groove; it has to be precisely machined to fit the carbon fibre perfectly, without any gaps or wobbles. The carbon fibre itself comes to us as a thin sheet, and we meticulously cut it to the exact width and length required for each individual ring. This isn’t a task for the faint-hearted; it requires a steady hand and an eagle eye, because even a tiny imperfection at this stage will show up loud and clear in the finished piece. It’s all about harmony between the materials, making sure they sit together as if they were always one. This stage is where the ring truly starts to show its unique personality, marrying the ruggedness of the metal with the modern elegance of the carbon. Much like the intricate patterns and designs we carefully consider for our Hawaii Rose Gold Necklaces Handmade, every detail in this inlay is about thoughtful execution and visual balance.

The next bit is bonding the carbon fibre into the tungsten. This involves a special resin that securely locks the inlay into place, creating a seamless, robust connection. The trick here is to ensure an even application, no air bubbles, and a perfectly level surface. It's a bit like a miniature engineering project, balancing strength with aesthetics. After the resin cures, which takes a precise amount of time under controlled conditions, we then begin the process of sanding it down, gradually bringing the carbon fibre perfectly flush with the tungsten. This isn't a quick job; it's a patient, step-by-step process with increasingly finer grits, slowly revealing the beautiful, subtle pattern of the carbon fibre within its sturdy metal embrace. Each pass is measured and controlled, ensuring a flawless integration. We are always aiming for that smooth, continuous surface that feels delightful to the touch and looks utterly seamless to the eye. This commitment to achieving perfection in every bond and every surface ensures the lasting beauty and integrity of the final piece.

The Grand Finale: Polishing and Personalisation

After the carbon fibre is perfectly integrated, it’s time for the ultimate glow-up: the polishing. This isn’t just a quick buff; it’s a multi-stage process that brings out the true lustre of both the tungsten and the carbon fibre. We start with coarser compounds to smooth out any last microscopic imperfections, gradually moving to finer and finer polishes until the ring practically gleams. It takes patience, a steady hand, and a keen eye to get that mirror-like finish, especially when you’re working with two different materials that respond slightly differently to the polishing wheel. It’s a bit of an art form, knowing just how much pressure to apply, for how long, and with which compound, to achieve that signature shine that really makes the ring pop. This dedication to the final finish ensures that every single ring leaving our workshop looks absolutely stunning. We truly believe that the final presentation, that brilliant sheen, is just as important as the initial design, making it a fitting token for a special milestone, like a 30th Birthday Gift.

And then, the really special part – the custom engraving. This is where a piece transitions from just a beautiful object to something deeply personal. We use a high-precision laser for this, ensuring that whatever message or date you choose is etched with absolute clarity and permanence onto the base of the ring. It’s a precise operation, requiring careful setup and calibration for each individual ring, as every piece is slightly different. Before we even think about touching the ring, we run test patterns, double-check the spelling, and confirm the exact placement. There’s no undo button here, so getting it right the first time is non-negotiable. It’s a quiet moment, watching that laser beam work its magic, knowing that we’re adding a unique, lasting touch to someone’s future heirloom. This bespoke element is what truly sets our work apart, creating a one-of-a-kind connection with the wearer, embedding a personal story right into the heart of the metal.

Finally, once the engraving is done and the ring has passed its final, super-rigorous quality check – and believe me, we’re picky! – it's ready for its new home. We inspect every curve, every edge, every millimetre of the inlay, ensuring it meets our sky-high standards. We package it up with the utmost care, knowing that it’s not just a ring, but a symbol, a memory, a piece of someone’s story. It's a moment of quiet pride, seeing a raw idea transform through careful hands and dedicated processes into a finished piece that we know will bring lasting happiness. We're truly chuffed to bits with every single one. And if you’re ever curious to peek a bit more behind the scenes, or want to understand any other aspect of our craft, you can always find out more, just follow this link: Learn more here.